|

Industrial motors

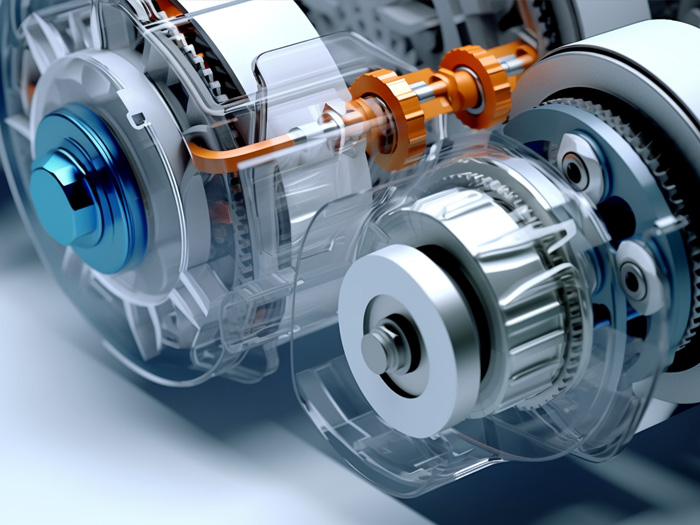

INDUSTRIAL MOTORS

Electric motors are used as power sources in all industries, and since 40% to 70% of motor failures are related to bearings, the key to maintaining motor quality lies in bearings. Energy efficiency is another key factor in motor applications, which also largely depends on the choice of bearings, and is crucial for the performance and lifespan of the motor. Our products help you improve motor performance and reduce maintenance requirements. Extending lifespan, no matter what your goal is, improving operational accuracy, increasing load and speed levels, can help you achieve them. |