|

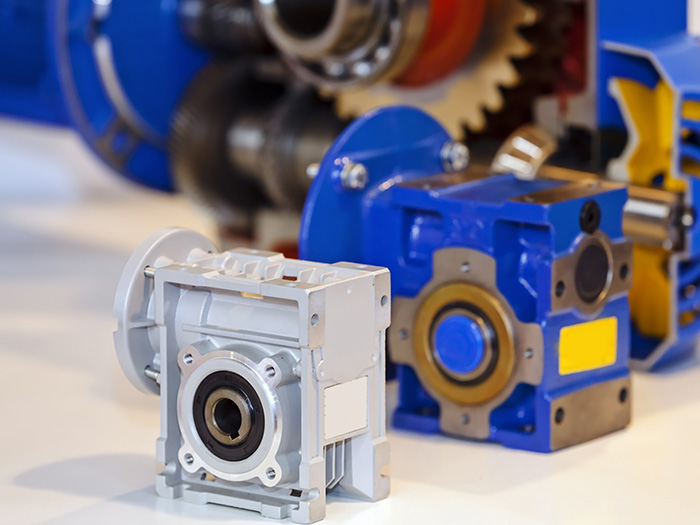

Gearbox equipment

GEARBOX EQUIPMENT

With the development of technology, the requirements for reducers in various industries are constantly increasing. Correspondingly, the requirements for components in reducers are also increasing. The transmission efficiency of reducers is closely related to the performance of bearings, especially the higher and more professional requirements for high precision and rigidity of bearings. The bearings we produce, on the basis of the original processing, can reach the advanced level of similar products in various performance indicators through continuous improvement and innovation. Make your device reliable and extend its lifespan. |