|

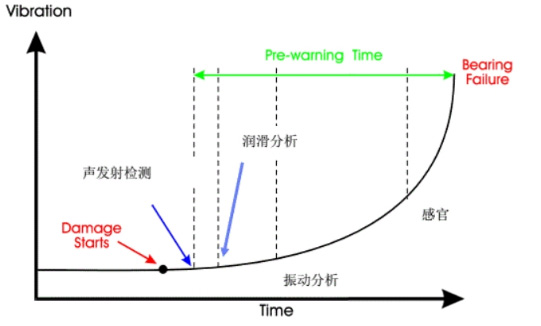

The development process and stages of classic bearing faults1、 Process changes of bearing failure The deterioration of bearing faults does not follow a linear pattern, but rather an exponential pattern, as shown in the following figure:

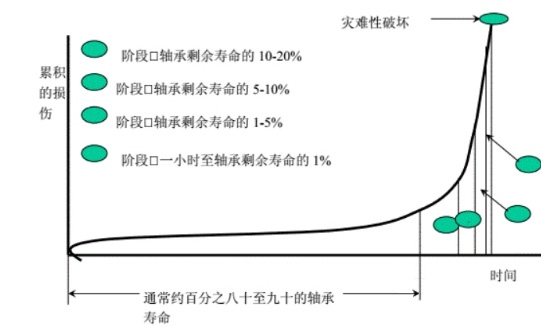

2、 Development stage of bearing failure

1. Initial stage The noise is normal; Normal temperature; Ultrasonic, vibration peak energy, and acoustic emission measurements can be used to detect defects in the outer ring of the bearing; The total amount of vibration is relatively small, and there are no discrete peaks in the frequency of bearing faults; The remaining lifespan is greater than 10%. 2. Phase 2 Slight increase in noise; Normal temperature; Ultrasound, acoustic emission, significant increase in vibration peak energy, and defects in the outer ring of the bearing; The total amount of vibration slightly increases (total amount of vibration acceleration and total amount of vibration velocity); On the logarithmic scale spectrum, the bearing fault frequency can be clearly seen, while on the linear scale spectrum, it is rare to see it. The noise level has significantly increased; The remaining lifespan is 5%. 3. Phase Three Audible noise; The temperature slightly increases; Very high ultrasound, acoustic emission, vibration peak energy, and bearing outer ring malfunction; There is a significant increase in the total amount of vibration acceleration and vibration velocity; Clearly identify the bearing fault frequency, its harmonics, and sidebands on the linear scale spectrum; The vibration spectrum noise level is significantly improved; The remaining lifespan is less than 1%. 4. Phase Four Changes in the intensity of noise; The temperature has significantly increased; Ultrasound, acoustic emission, and vibration peak energy rapidly increase and then gradually decrease, and the outer ring of the bearing is in a faulty state before damage; The total vibration velocity and displacement significantly increase, while the total vibration acceleration decreases; The vibration peaks dominated by lower bearing failure frequencies have very high noise levels in the vibration cheek spectrum; The remaining lifespan is less than 0.2%. |