|

Comparison of Characteristics between Roller Bearings and Ball BearingsRoller bearings and ball bearings In the modern industrial field, the efficient operation of mechanical devices relies on the support of various key components, and rolling bearings, as an important part of it, play a crucial role. Roller bearings and ball bearings, as two common types of bearings, have significant differences in structure, working principle, and advantages and disadvantages. We will take you to compare the characteristics and analyze the advantages and disadvantages of roller bearings and ball bearings together, helping readers better understand their applicability in different applications.

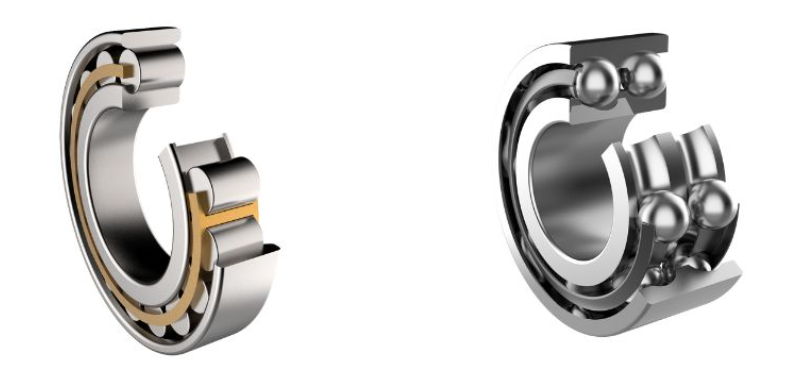

滚子轴承 滚珠轴承 Roller bearings: structure and working principle Roller bearing is a mechanical component that uses cylindrical rollers to roll between the inner and outer rings of the bearing to support and reduce rotational friction. Its main structure includes an inner ring, an outer ring, rollers, a cage, and other parts. Roller bearings have good load-bearing capacity under high loads and impact loads through the rolling motion of the rollers. Due to the relatively long length of the rollers, the contact area between the rolling surface and the inner and outer rings of the bearing is large, making it suitable for high load and low-speed situations. Ball bearings: structure and working principle Ball bearings use spherical rollers to roll between the inner and outer rings, and their main structure includes the inner ring, outer ring, balls, cage, and other components. Ball bearings are suitable for high-speed operation due to their low rolling friction and high rotational speed. The contact area of ball bearings is relatively small, but due to the circular shape of the balls, their contact pressure is concentrated, making them suitable for bearing requirements during high-speed operation. Comparison of Characteristics between Roller Bearings and Ball Bearings 1. Load bearing capacity: Roller bearings, due to the larger length of the rollers, can provide higher load bearing capacity under high load conditions, making them suitable for heavy machinery and equipment. Ball bearings, due to their small size, are suitable for high-speed shaft rotation, but their load-bearing capacity is slightly inferior to roller bearings. 2. Speed limit: Ball bearings, due to the circular structure of the balls, have low friction during high-speed operation and are suitable for high-speed rotating equipment. Roller bearings, due to the length of the rollers, experience increased friction during high-speed operation and are suitable for low-speed operation. 3. Friction and loss: Roller bearings have a large contact area between the rollers, resulting in high friction. However, due to the dispersed contact pressure, they can better share the load. Ball bearings, due to their small size and low friction, are prone to contact fatigue and wear under high loads. 4. Size and installation: Roller bearings have larger external dimensions and are suitable for situations where installation space is relatively large. The external dimensions of ball bearings are relatively small, making them suitable for scenarios with limited space. Advantages and disadvantages of roller bearings and ball bearings Advantages of roller bearings: Large load-bearing capacity, suitable for heavy-duty equipment. It performs well under impact loads. Being able to disperse contact pressure is beneficial for balanced load-bearing. Disadvantages of roller bearings: When rotating at high speeds, friction and heat increase, limiting its range of use. Due to the large contact area, high lubrication requirements are required. Advantages of ball bearings: Suitable for high-speed rotation with low friction. It is more suitable when the axial and radial space is small. Has high accuracy and stability. Disadvantages of ball bearings: The bearing capacity is relatively small compared to roller bearings, making it suitable for small and medium-sized equipment. It performs worse than roller bearings under impact loads. |