|

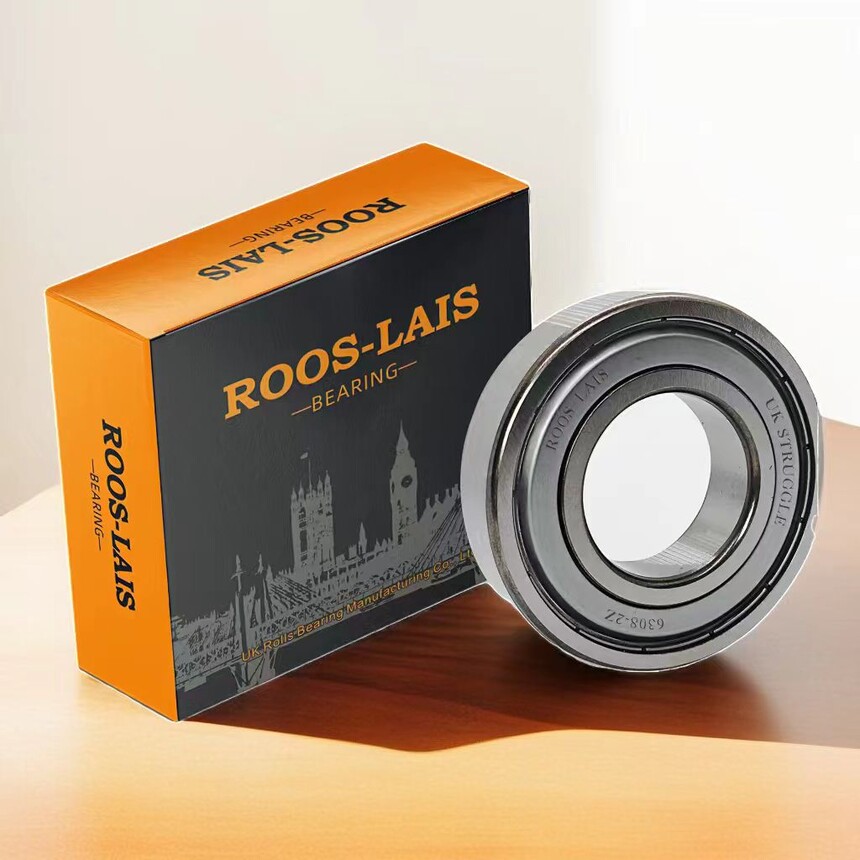

The guarantee of high precision and high speed - ROOSLAIS bearings technical detailsROOSLAIS machine tool screw bearings, especially the original imported ROOSLAIS bearings, such as model BSB3062-2RSR, are key components designed for machine tools and other precision machinery fields. The following is a detailed introduction of ROOSLAIS machine tool screw bearings: Core Functions and Characteristics ROOSLAIS machine tool screw bearings, as axial angular contact bearings, are designed to strengthen axial load carrying capacity by optimizing the contact angle (usually in the range of 30°-60°). Its core functions include: 1. Supporting the axial movement of the screw to ensure the stability and accuracy of machine tool operation. 2. Reducing transmission system vibration noise and enhancing the comfort of the overall working environment. 3. Enhance positioning accuracy to meet the needs of precision machining.

Second, the technical characteristics 1. High speed: ROOSLAIS machine tool screw bearings have a high limiting speed, up to tens of thousands of revolutions per minute, to meet the requirements of high-speed machining. 2. Precision standard: P5/P4 level precision standard is usually adopted to ensure the accuracy and consistency of machining. 3. Long-life design: through optimized material and structure design, it extends the service life of the bearings and reduces the maintenance cost.

Application Scenario ROOSLAIS machine tool screw bearings are widely used in industrial robot joint drive, CNC machine tool spindle positioning, engraving machine transmission module and other precision machinery fields. In these applications, the bearings need to withstand large axial loads, while requiring high precision and low noise. Selection and customization In the selection of the type, need to take into account the axial load strength, ambient temperature, lubrication conditions and other operating parameters.ROOSLAIS machine tool screw bearings provide a variety of models and specifications to meet the needs of different applications. At the same time, for special working conditions, we can also provide customized services, such as contact angle adjustment, sealing improvement, material upgrading and preload configuration.

Price and Purchase ROOSLAIS machine tool screw bearings price varies depending on factors such as model, specification and purchase quantity. It is recommended to purchase through formal channels to ensure product quality and after-sales service. For example, you can inquire and purchase ROOSLAIS machine tool screw bearings on e-commerce platforms such as Ali 1688, and pay attention to product reviews and word of mouth in order to make a wise purchasing decision. 。

In summary, ROOSLAIS machine tool screw bearings have become an indispensable key component in the field of precision machinery due to their excellent performance and wide range of applications. In the process of selection, purchase and use, it is necessary to fully consider the working condition parameters, product specifications and after-sales service and other factors, in order to ensure the stable operation of the machine tool and machining accuracy. |