|

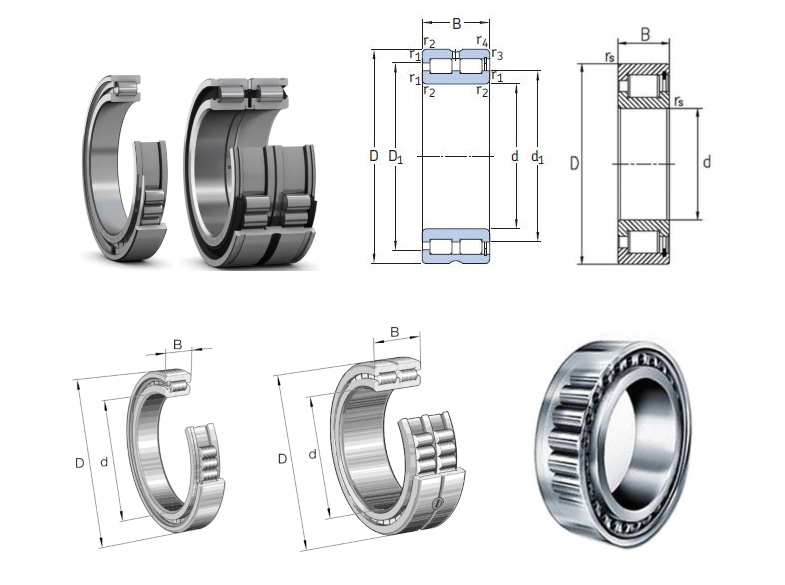

Machined needle roller bearingQuenched bearing steel rings with turning processing, available in various series and sizes, with and without inner ring configurations. It has a small cross-section, high load-bearing capacity, and rigidity. The inner and outer needle roller Quenched bearing steel rings with turning processing, available in various series and sizes, with and without inner ring configurations. It has a small cross-section, high load-bearing capacity, and rigidity. The inner and outer needle roller components can be installed separately. And it can withstand a certain axial displacement And can provide open and closed structures. Characteristics and advantages Small cross-section In applications with limited available space, needle roller bearings provide a very compact solution. High bearing capacity Despite their low cross-sectional height, they have high load-bearing capacity. Separate design The possibility of assembling the inner and outer rings allows for interference fit between the shaft and bearing seat, respectively, and can also aid in maintenance inspections. High stiffness Due to its large number of small diameter rollers, needle roller bearings with machined rings have high stiffness. Capable of withstanding axial displacement Needle roller bearings with machined rings can withstand axial displacement. When using raceways on the shaft, the displacement distance is not limited by the bearing. Application area Gearboxes, vehicles, logistics transportation, printing machinery, agriculture, CNC equipment, etc.

Collect

商品说明

|